machining of ultra-high vacuum (UHV) components and assemblies

General specifications

Accordingly, each one of the machining requirements for UHV conditions must be met:

Inorganic cutting fluids

Viscous organic lubricants must not be used.

Clean machines

Cleaning and replacement of the cutting fluid after each change of material to be machined for UHV items.

special tools

New, special tools for each new material. Cleaning is essential and important throughout the entire process.

It is necessary to clean the elements before, during and after each manufacturing process, taking great pains to ensure there is no cross contamination between “clean” and “dirty” components.

Materials:

All materials used must be compatible with UHV, such as:

STAINLESS STEEL

AISI 304L, 304LN, 316L, 316LN, 321, 347

ALUMINIUM

5086, A-6061-T6, A-6063-T6

PEEK

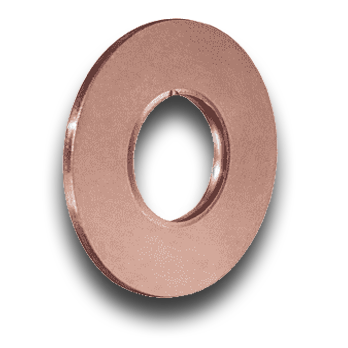

COPPER

machining of ultra-high vacuum (UHV) components and assemblies

With this process, TOTAL PLANNING guarantees compliance with the UHV machining requirements of its most demanding customers.