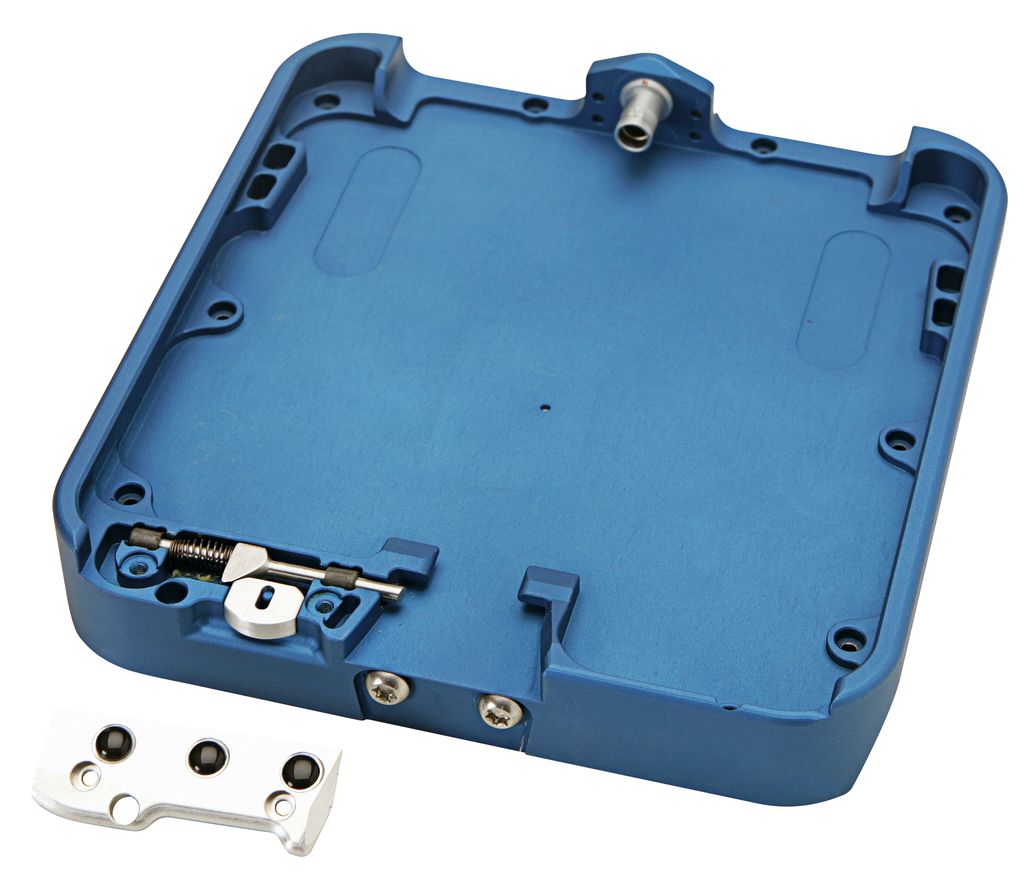

- It is a material that is very corrosion-resistant. Depending on the alloy used, various post-treatments can be applied, for all types of outdoor use.

- It is a good heat (it accumulates heat for a short time) and electric conductor.

- It is lightweight. Its weight is approximately one third of the weight of steel. For this reason, aluminium is frequently used in the aeronautical sector or in machinery manufacturing, where the weight of the pieces is an important consideration.

- Low-density. It makes it easy to machine and causes little wear to the tools used. All this results in low energy consumption.

- It is a soft material; which allows it to be easily worked on the machine; producing an electrical consumption 3 times lower than the machining of steel and faster than the latter.

- It is an affordable material (very abundant worldwide) and 100% recyclable.

These combined characteristics, mainly the low density and its high resistance to corrosion, make aluminium one of the most universally used materials. Its multiple alloys are applied to sectors such as the automotive, machine-tools, railway, aeronautical, etc.

Good way of explaining, and nice piece of writing to

get information.