Parts

The range of machined parts used by Total Planning is very wide: we use materials of different sizes and different morphology; turned or milled parts; starting from bar, plate, plate or cast iron materials.

Treatments and finishes

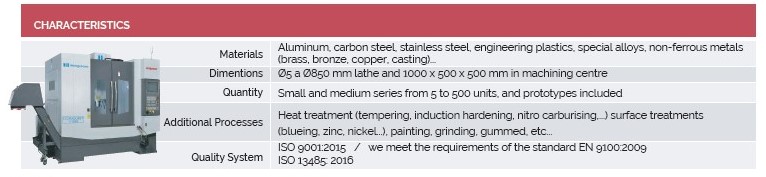

Regarding the finishing of the pieces, we are used to work with thermal treatments (tempered, induction, nitro carburetion, foundation, etc.) and surface treatments (blued, galvanized, nickel-plated, anodized, painted, chromed, etc).

Materials

In TotalPlanning we work from the most common steels to the most special steels (stainless, carbon, titanium ...) through the wide variety of non-ferrous metals (aluminum, bronze, brass,) to technical plastics.

MACHINING UHV

MACHINING OF ULTRA-HIGH VACUUM (UHV) COMPONENTS AND ASSEMBLIES

SUBTRACTIVE MACHINING

Subtractive machining is a process that comprises the shaping of the raw material, in bars or sheets.

5 AXIS MACHINING

On 5-axis machining centers, the cutting tool can move through the X, Y, and Z axes; turning on axes A and B. In this way, any part of the piece can be accessed in a single phase.

Urgent Prototipes

We offer an urgent prototyping service; which aims to provide a quick solution to our customers.

Characteristics of our machining centers

TOTAL PLANNING, S.L specializes in the machining of short and medium series, with the ability to make prototypes of unique pieces and tools.

THE COMPANY IN NUMBERS

Precision machining solutions

Contact us and a qualified agent will answer all your questions or suggestions.