total planning

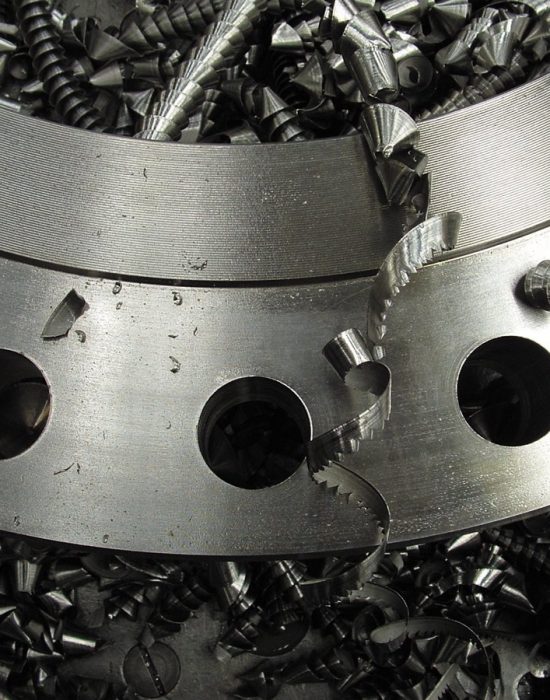

Subtractive machining is a process that comprises the shaping of the raw material, in bars or sheets.

The subtractive process is done through the penetration of a cutting tool into the raw material. Using a suitable relative motion between the cutting tool and the workpiece, the tool creates the desired shape with its cutting edges or blades. Logically, the cutting tool material must be harder than the workpiece being cut.

Subtractive machining processes

There are three kinds of subtractive machining processes:

Roughing: removal of a lot of material with little precision; it is an intermediary process used to get closer to the final dimensions of the workpiece quickly. It requires a high feed rate and cutting speed.

Finishing: elimination of little material with a lot of precision; the objective of this process is to give the different surfaces of the workpiece the surface finish they require. It is used to obtain a finish with low surface roughness. Low feed rate and high cutting speeds.

Honing or superfinishing: Used for a good surface finish and very precise measurements. Very high feed rate and cutting speeds; using abrasive particles.

Types of subtractive machining

The most common types of subtractive machining are sawing, filing, drilling, threading, broaching, shaping, turning and milling.

Although we can offer all these techniques at Total Planning, we will focus on the two processes that form part of our know-how: turning and milling.

Precision machining solutions

Contact us and a qualified agent will answer all your questions or suggestions.