At Total Planning we machine all kinds of materials: aluminium, steel, stainless steel, copper, brass, etc., and increasingly more technical plastics, in their different classes (POM, Delrin, PET, bakelite, methacrylate, Celotex, etc.)

Over the last few years, thermoplastics have evolved, improving technically and combining to obtain new mechanical, physical and chemical resistances, as well as new uses.

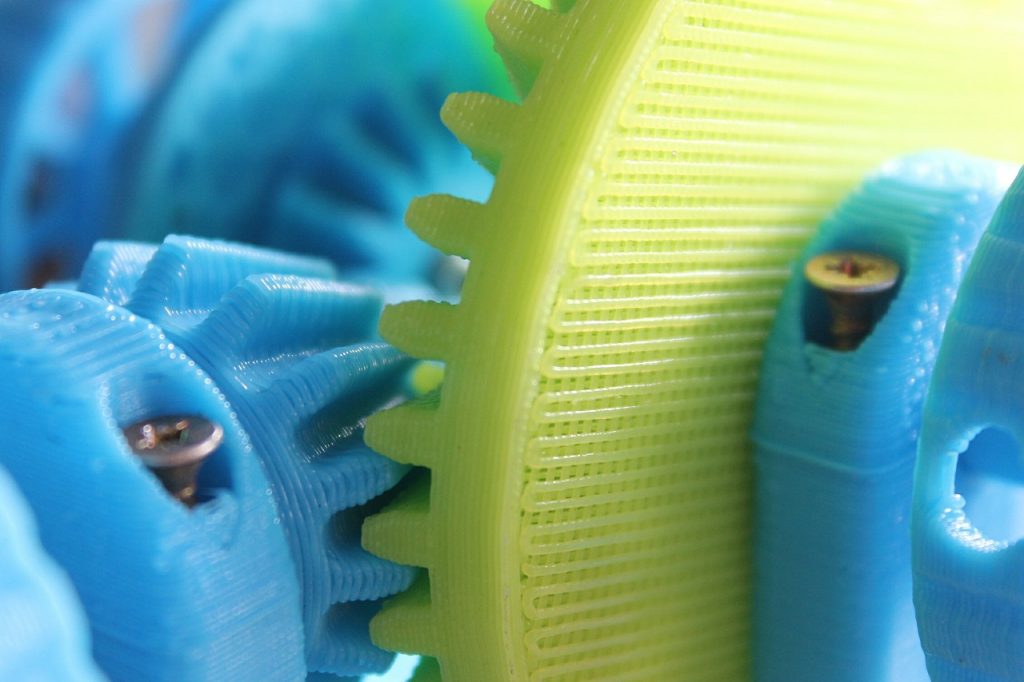

Plastic is typically used when a low-weight material with high mechanical resistance is needed. This material has low density, and good absorption of noise and vibrations. For these reasons, it is a product that is used in different sectors, such as the automotive, medical, aeronautical and general machinery sectors, among others.

However, it is important to take into consideration that to machine this material, special tools must be used, the workpiece must be attached to the machine properly, and the machine must be used more slowly; otherwise, we run the risk of cracking or deforming the workpiece.